-

Ligue para nós 0592 6536915

-

Envia-nos um email sophia@fzolink.com

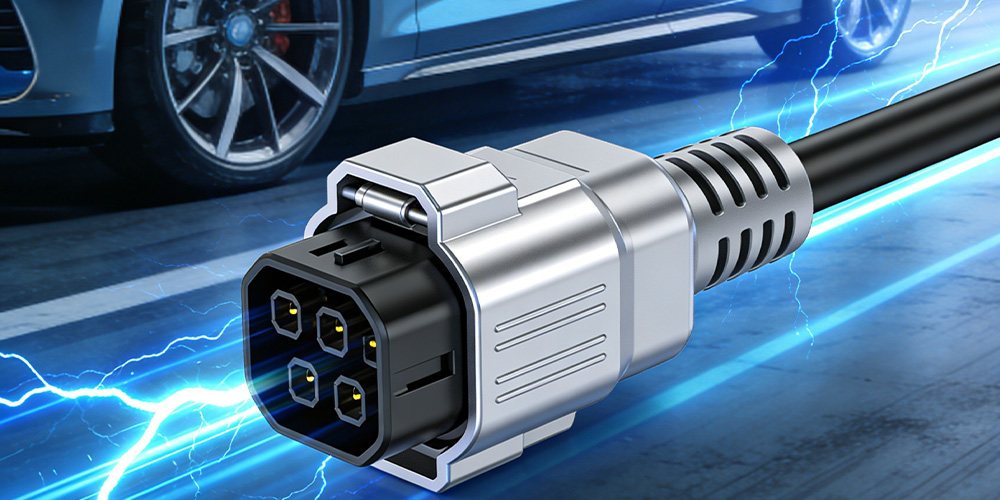

In recent years, the global new energy vehicle (NEV) industry has experienced explosive growth, driven by the dual goals of carbon neutrality and energy structure transformation. For consumers, the two core pain points restricting the widespread adoption of electric vehicles (EVs) have long been limited driving range and concerns about safety performance. Behind the steady breakthroughs in these two areas, high-voltage connectors, as a key component of the NEV power system, play an irreplaceable role.

Click to learn more about all High-Voltage Connectors

Table of contents:

1. The Direct Link to Range Extension: How High-Voltage Connectors Boost EV Range

2. The Cornerstone of Safety Upgrade: Safety Protection Mechanisms of High-Voltage Connector

3. Market Status and Future Outlook

4. Conclusion

The Direct Link to Range Extension: How High-Voltage Connectors Boost EV Range

The driving range of EVs has always been a key factor affecting consumer purchasing decisions. Many consumers' "range anxiety" is not only related to the energy density of the battery but also closely linked to the energy transmission efficiency of the entire power system. High-voltage connectors, as an important link in the energy transmission chain, have a direct impact on the energy loss of the power system, thereby affecting the actual driving range of the vehicle.

Firstly, reducing energy loss through low-resistance contact design. During the transmission of high-voltage and high-current electrical energy, the contact resistance of the connector will cause a certain amount of energy loss (usually manifested as heat generation). High-performance high-voltage connectors adopt advanced contact materials (such as copper alloy with high conductivity) and optimized contact structure design, which can minimize contact resistance. For example, some high-end NEV high-voltage connectors can control the contact resistance within a few milliohms, greatly reducing the energy loss during electrical energy transmission and ensuring that more electrical energy stored in the battery can be used for driving the vehicle.

Secondly, optimizing power transmission efficiency to adapt to high-load working conditions. When EVs are in high-load working conditions such as high-speed driving, climbing, or rapid acceleration, the motor's demand for electrical energy will increase sharply. High-voltage connectors with excellent performance can stably transmit large currents under high-load conditions, ensuring that the motor obtains sufficient energy supply in a timely manner, avoiding power loss caused by insufficient energy transmission, and thus maintaining the vehicle's power performance while reducing unnecessary energy waste.

Thirdly, realizing lightweight and miniaturized design to reduce vehicle energy consumption. The overall weight of the vehicle is an important factor affecting EV range—lighter vehicle weight means lower energy consumption. High-voltage connector manufacturers adopt lightweight materials (such as high-strength engineering plastics) and optimized structural design to reduce the weight and volume of the connector on the premise of ensuring performance. For example, the weight of a single high-voltage connector can be reduced by 10%-20% through lightweight design. Although the weight reduction of a single connector is limited, the cumulative effect of multiple connectors in the entire vehicle can effectively reduce the overall weight of the vehicle and further improve the driving range.

Relevant case data shows that after a certain mainstream NEV model replaced the original high-voltage connectors with high-performance low-resistance connectors, the energy loss of the power system was reduced by about 3%, and the actual driving range under comprehensive working conditions was increased by 8-12 km. This fully verifies the positive role of high-voltage connectors in improving EV range.

Click to return to the directory

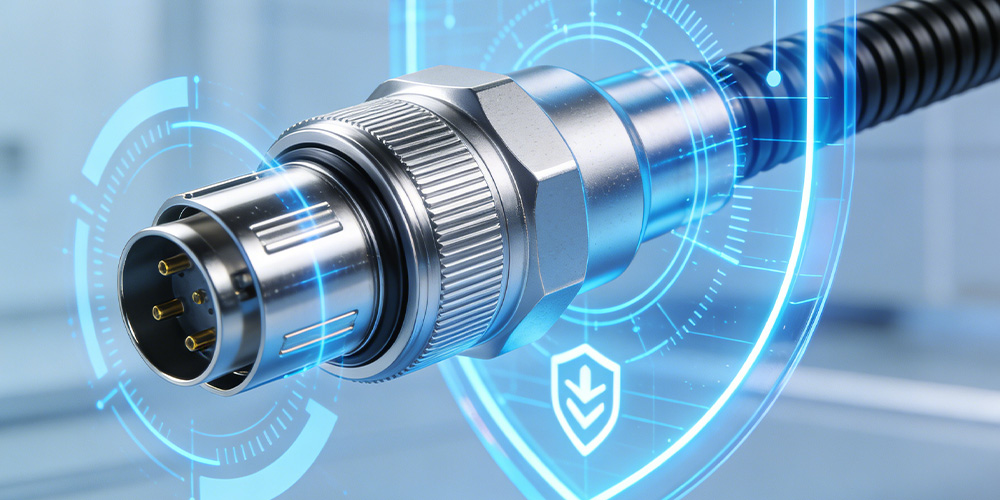

The Cornerstone of Safety Upgrade: Safety Protection Mechanisms of High-Voltage Connector

Safety is the primary prerequisite for the development of NEVs. The high-voltage power system is the core of NEVs, and its safety directly relates to the life and property safety of users. As an important connecting component of the high-voltage power system, high-voltage connectors are equipped with a multi-layer safety protection mechanism to build a solid "safety barrier" for the operation of NEVs.

The high-voltage interlock (HVIL) system is the core safety design of high-voltage connectors. Its working principle is to connect a low-voltage monitoring circuit in the high-voltage connector. When the connector is not fully connected or is accidentally disconnected, the HVIL system will immediately detect the circuit disconnection signal and feed it back to the vehicle control unit (VCU). The VCU will then issue an instruction to cut off the high-voltage power supply of the battery pack in time, avoiding electric shock hazards caused by exposed high-voltage terminals. This mechanism ensures that the high-voltage circuit is only connected when the connector is fully locked, fundamentally eliminating the safety risk of electric shock during the connection and disconnection of the high-voltage system.

Overcurrent and overvoltage protection is another important safety guarantee of high-voltage connectors. During the operation of NEVs, factors such as short circuits in the power system, abnormal operation of the motor, or failure of the charging pile may lead to overcurrent or overvoltage in the high-voltage circuit. High-voltage connectors are equipped with overcurrent and overvoltage protection components (such as fuses, voltage sensors, etc.). When the current or voltage in the circuit exceeds the safe threshold, these components will trigger a cut-off mechanism in time to disconnect the high-voltage circuit, avoiding damage to core components such as the battery and motor caused by overcurrent and overvoltage, and even preventing safety accidents such as fires.

In addition, high-voltage connectors also have excellent environmental adaptation and protection capabilities. NEVs need to face complex working environments such as rainy days, high-temperature deserts, low-temperature plateaus, and dusty roads during use. High-voltage connectors adopt a sealed design to achieve a high level of waterproof and dustproof performance (usually reaching IP67 or higher protection level), which can prevent water, dust, and other impurities from entering the connector interior and causing short circuits. At the same time, the connector shell and internal components are made of high-temperature and corrosion-resistant materials, which can maintain stable performance in the temperature range of -40℃ to 125℃, adapting to the harsh working conditions of NEVs.

It should be emphasized that all NEV high-voltage connectors must comply with strict international and regional safety standards. For example, they need to meet the requirements of the International Electrotechnical Commission (IEC) 61984 standard, the Society of Automotive Engineers (SAE) J1772 standard, and China's national standard GB/T 18487.1. These standards specify strict requirements for the safety performance, test methods, and quality control of high-voltage connectors, ensuring that the high-voltage connectors used in NEVs have reliable safety performance.

Click to return to the directory

Market Status and Future Outlook

Driven by the continuous expansion of global NEV production and sales, the market demand for high-voltage connectors is showing a rapid growth trend. According to relevant data, the global NEV high-voltage connector market size will reach 12.3 billion US dollars in 2024, and it is expected to exceed 25 billion US dollars by 2030, with a compound annual growth rate of more than 15%. The main driving factors of market growth include the continuous increase in NEV penetration rate, the acceleration of the upgrade to 800V high-voltage platforms, and the increasing demand for intelligent and integrated connectors.

However, the NEV high-voltage connector market also faces many challenges. On the one hand, with the intensification of market competition, manufacturers need to balance the relationship between high performance, low cost, and reliability. High-performance materials and advanced technologies will increase the production cost of connectors, while consumers and vehicle manufacturers have strict requirements on product prices. How to reduce costs on the premise of ensuring performance has become an important problem faced by manufacturers. On the other hand, the technological iteration speed of NEVs is very fast, and high-voltage connectors need to keep up with the pace of technological development of vehicle manufacturers, such as adapting to the upgrading of high-voltage platforms, matching the needs of intelligent networking, etc. This puts forward higher requirements on the R&D capabilities and innovation speed of connector manufacturers.

Looking to the future, the NEV high-voltage connector market will show a more obvious development trend of high voltage, intelligence, lightweight, and integration. With the widespread application of 800V+ high-voltage platforms, high-voltage connectors will move towards higher voltage and current levels; the integration of more intelligent sensors and communication modules will make connectors an important part of the vehicle's intelligent system; the continuous innovation of lightweight materials will further reduce the weight of connectors and improve energy efficiency; the integration and modularization level will continue to improve, promoting the simplification and high efficiency of the power system.

Click to return to the directory

Conclusion

As a key component of the NEV power system, high-voltage connectors are not only the "blood vessels" for energy transmission but also the "safety barrier" for the operation of the vehicle. Their performance directly affects the driving range and safety performance of EVs, and is an indispensable core link in the high-quality development of the NEV industry.

With the continuous advancement of technology, high-voltage connectors are constantly upgrading towards higher voltage, higher efficiency, intelligence, and integration, providing strong support for breaking through the bottlenecks of EV range and safety. In the future, with the continuous expansion of the NEV market and the in-depth development of intelligent and high-voltage technologies, high-voltage connectors will play a more important role. It is believed that through the joint efforts of upstream and downstream enterprises in the industry, high-voltage connector technology will continue to innovate, contributing more to the sustainable development of the global new energy vehicle industry.